Boiler Condensate Pipes

Protect your Boiler from Freezing

As we approach the end of Autumn the air of late is definitely feeling chilly! Jack Frost had well and truly put his stamp on the grass this Saturday morning at my local park.

With this change in the weather most of us will by now been getting used to putting the heating on. Now is the time to get your boiler serviced as it approaches its most hard working period of the year to check everything is in tip top condition when you need it most. Before we get too close to the festivities get your boiler service booked with a reliable Gas-Safe registered engineer.

There is something YOU can do……

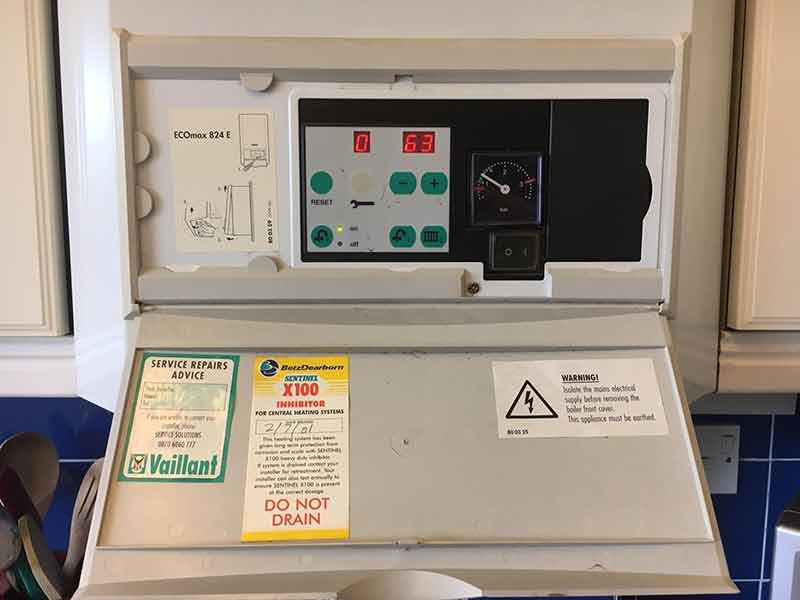

……… particularly if you have any crazy pipework like that shown in the picture above.

Most modern combi boilers have a small plastic pipe that carries waste water away from the boiler. Ideally, this should terminate internally, but if it does run outside, there are 3 things which should be done:

- The pipework needs to be lagged

- The pipe diameter needs to be upgraded by at least one size. (i.e the condensate pipe needs to be upgraded to at least 32mm waste pipe)

- The overall pipe run should be as short as possible.

If this pipework freezes and your boiler can’t get rid of this water it will stop working probably at the most inconvenient time.

Limit the chances of this happening by getting busy with some lagging and plastic cable ties.

Armaflex (black coloured) lagging is recommended as it is designed for outdoor installations.

What to do if your Condensate Pipe freezes

1. Pour Warm water over the Pipe

This is easier to do, if the pipe is outside.

Be careful that the water which lands on the ground doesn’t freeze and cause a dangerous slip hazard

2. Use a Hot Water Bottle or Hairdryer (on low heat)

This is easier to do, if the pipe is inside.

So, before you suddenly discover that your boiler isn’t working properly, and your home is getting very cold, go and check that your condensate pipe is Cold Weather Ready